Kugamuchirwa kubvunza nekutaurirana

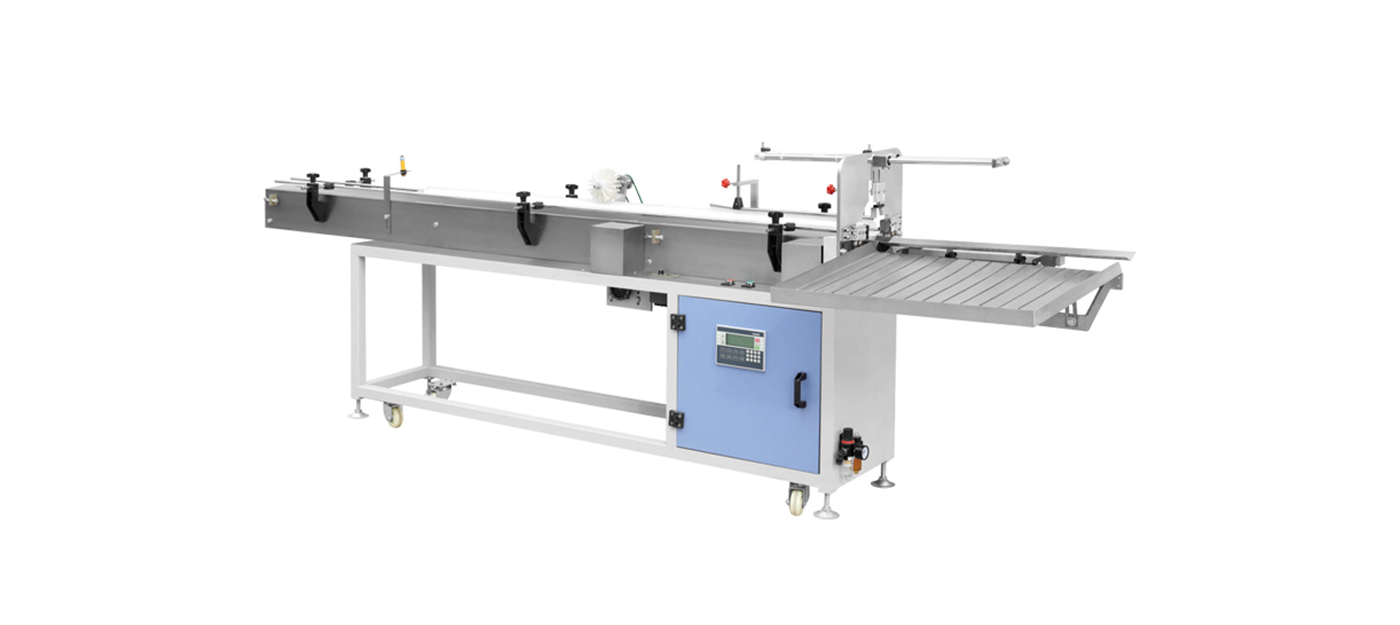

RM-4 ina-chiteshi Thermoforming Machine

Tsanangudzo

Iyo 4-station yakanaka uye yakaipa pressure thermoforming muchina inyanzvi yekugadzira michina inogona kushandiswa kugadzira kuraswa epurasitiki yemichero mabhokisi, maruva mapoto, kofi mukombe zvivharo uye domed zvivharo ane maburi, etc. Iyo midziyo inoshongedzerwa nekukurumidza mold shanduko system uye ine mukana weyakagadzirirwa dhizaini yekupisa bhokisi. Mudziyo uyu unotora tekinoroji yakanaka uye yakaipa yekumanikidza thermoforming tekinoroji kuti igadzirise pepa repurasitiki mune inodiwa chimiro, saizi uye inoenderana punching dhizaini nekudziisa pepa repurasitiki uye nekumanikidza yakanaka uye yakaipa gasi rekumanikidza. Mudziyo uyu une seti ina dzenzvimbo dzekushandira dzekugadzira, kuboora gomba, kupinza punching, uye kurongedza uye palletizing, izvo zvinogona kusangana nezvinodiwa zvemaindasitiri akasiyana uye kuve nechokwadi chemhando uye kuenderana kwezvigadzirwa.

Machine Parameters

| Molding nzvimbo | Clamping force | Kumhanya kumhanya | Sheet ukobvu | Kuumba urefu | Kugadzira kumanikidza | Zvishandiso |

| Max. Mold Dimensions | Clamping Force | Dry Cycle Speed | Max. Sheet Ukobvu | Max.Foming Urefu | Max.Air Pressure | Yakakodzera Material |

| 820x620mm | 80T | 61/kutenderera | 1.5mm | 100mm | 6 Bar | PP, PS, PET, CPET, OPS, PLA |

Features

Automatic control

Iyo midziyo inotora advanced otomatiki control system, iyo inogona kunyatso kudzora ma paramita akadai sekupisa tembiricha, nguva yekuumba uye kudzvanywa kuti ive nechokwadi chekugadzikana uye kuenderana kwemaitiro ekuumba.

Kurumidza kuchinja mold

Iyo 4-chiteshi thermoforming muchina wakashongedzerwa nekukurumidza mold shanduko sisitimu, iyo inofambisa shanduko yekukurumidza mold uye inogadzirisa kune zvinodiwa zvekugadzira zvezvigadzirwa zvakasiyana, nekudaro zvichivandudza kuchinjika kwekugadzirwa.

Kuchengetedza magetsi

Midziyo yacho inotora tekinoroji yekuchengetedza simba, iyo inonyatso kudzikisa kushandiswa kwesimba, inoderedza mutengo wekugadzira, uye inoenderana nenharaunda panguva imwe chete.

Easy kushanda

Iyo 4-station thermoforming muchina yakashongedzerwa ine intuitive operation interface, iri nyore kushandisa uye nyore kudzidza, inoderedza mutengo wekudzidzisa vashandi uye mitengo yekukanganisa kwekugadzira.

Application

Iyo 4-chiteshi thermoforming muchina unoshandiswa zvakanyanya muindasitiri yekurongedza chikafu, uye inonyanya kukodzera kumabhizinesi anogadzira zvigadzirwa zvepurasitiki pamwero wakakura nekuda kwehunyanzvi hwayo hwepamusoro, huwandu hwepamusoro uye kuchinjika.

Tutorial