RM 2RH Kaviri Chiteshi IMC Thermoforming Machine

Machine Parameters

| ◆Muenzaniso: | RM-2R |

| ◆Max.Kuumba Nzvimbo: | 820*620mm |

| ◆Max.Kuumba Urefu: | 80mm |

| ◆Max.Sheet Ukobvu(mm): | 2mm |

| ◆Max Air Pressure(Bar): | 8 |

| ◆Dry Cycle Speed: | 48/cyl |

| ◆Kuombera Simba: | 65T |

| ◆Voltge: | 380V |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆ Reducer: | GNORD |

| ◆Kushandisa: | matireyi, midziyo, mabhokisi, zvivharo, nezvimwe. |

| ◆ Zvikamu Zvikuru: | PLC, Injini, Kubereka, Gearbox, Mota, Giya, Pombi |

| ◆Zvishandiso Zvakakodzera: | PP.PS.PET.CPET.OPS.PLA |

| Max.Mold Dimensions | Clamping Force | Dry Cycle Speed | Max.Sheet Ukobvu | Max.Foming Urefu | Max.Air Pressure | Yakakodzera Material |

| 820x620mm | 85T | 48/kutenderera | 2.8mm | 180mm | 8 Bar | PP, PS, PET, CPET, OPS, PLA |

Product Vhidhiyo

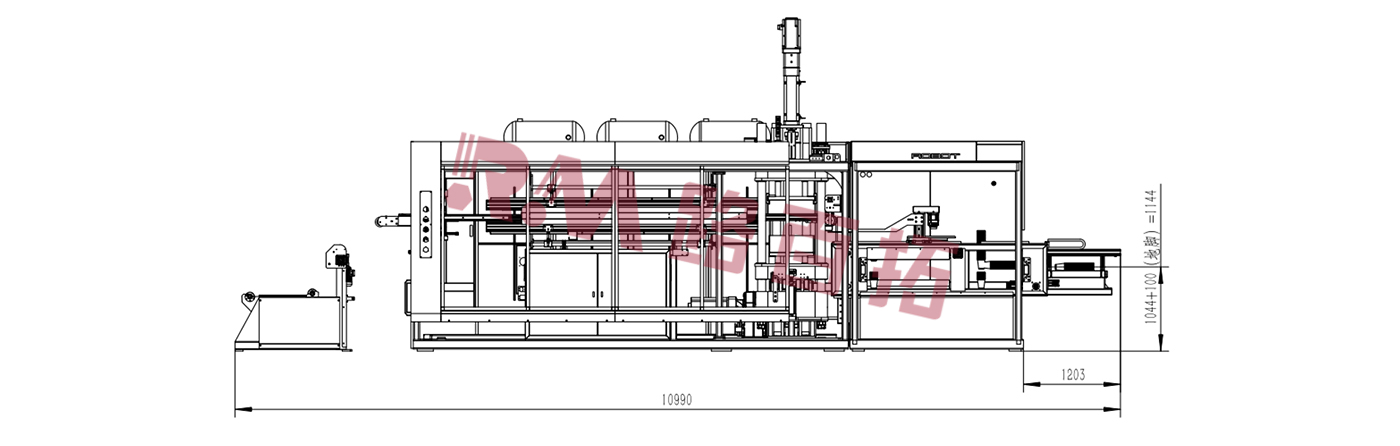

Dhiyagiramu yebasa

Main Features

✦ Sangana nenhanho nyowani yekubudirira neyedu-ye-iyo-yepamusoro otomatiki High-Speed Kugadzira uye Kucheka Machine.Inoratidzira maviri-zviteshi dhizaini, inoita kuumba nekucheka panguva imwe chete, ichiwedzera zvakanyanya kugadzirwa kwekuita.Iyo in-die yekucheka sisitimu inovimbisa kukurumidza uye kwakaringana kuchekwa, zvichiita kuti maitiro ekugadzira ashande.

✦Modhi yedu inopa zvese zvakanaka uye zvisina kunaka kumanikidza kuumba kugona.Nekushandisa kupisa uye kumanikidza, pepa repurasitiki rinoshandurwa kuita chimiro chinodiwa chechigadzirwa.Positive dzvinyiriro yekugadzira inovimbisa yakatsetseka uye inowirirana chigadzirwa chepamusoro, nepo kusasimba kuumbwa kunovimbisa huchokwadi hweiyo concave uye convex maficha, zvichikonzera kugadzikana uye kwepamusoro chigadzirwa mhando.

✦Akashongedzerwa neinternet palletizing system, muchina wedu unowana otomatiki stacking yezvakapera zvigadzirwa.Iyi yakagadziridzwa stacking process inosimudzira zvakanyanya kugadzirwa uye inoderedza kuwanda kwevashandi, ichibvumira timu yako kuti itarise pane mamwe mabasa akakosha.

✦Muchina wedu wakanyatsokodzera kugadzira zvigadzirwa zvidiki-kureba senge kapu dzesoso dzinoraswa, ndiro, uye mavharo.Nekudaro, inogona kuchinjika nyore kune akasiyana chigadzirwa saizi uye maumbirwo.Nekungoshandura molds uye kugadzirisa parameters, zvakasiyana-siyana zvezvigadzirwa zvinogona kugadzirwa.

✦Chengetedza mari mukubudirira uye mhando neAutomatic High-Speed Kugadzira uye Kucheka Machine.Panguva imwe chete kuumba uye kucheka, kwakanaka uye kwakashata kumanikidza masimba, otomatiki stacking, uye kuchinjika mukugadzirwa kwechigadzirwa - zvese mune imwe mhinduro ine simba.Gara pamberi pemakwikwi uye simudza kugona kwako kugadzira nemuchina wedu wekucheka-kumucheto!

Nzvimbo Yekushandisa

Iyi 2-chiteshi thermoforming muchina unoshandiswa zvakanyanya mukutakura chikafu uye maindasitiri ekubika.Nezvayo zvakanakira uye kuchinjika, inopa mabhizinesi nemhando yepamusoro uye yepamusoro-soro yekugadzira mhinduro.

Tutorial

Nhanganyaya:

Thermoforming inyanzvi uye inoshanda yekugadzira nzira inoshandiswa kune akasiyana maindasitiri.Kuve nechokwadi chekugadzira chisina musono uye chepamusoro-notch mhando, kugadzirira kwakaringana kwemidziyo, mabatirwo emidziyo, uye kugadzirisa kwakakosha.

Kugadzirira Kwemidziyo:

Usati watanga kugadzira, simbisa kubatana kwakasimba uye magetsi emuchina wako we2-station thermoforming muchina.Ita ongororo yakakwana yekudziya, kutonhora, kudzvanywa masisitimu, uye mamwe mabasa kuvimbisa kushanda kwavo kwakajairika.Chengetedza kuisa zviumbwa zvinodiwa, kuve nechokwadi kuti zvakanyatsoenderana kudzivirira chero zvingangoitika zvisina kunaka panguva yekugadzira.

Raw Material Gadziriro:

Tanga nekusarudza pepa repurasitiki rakakodzera kuumbwa, uchiona kuti rinoenderana nezvinodiwa zveprojekiti.Nyatsoteerera ukuru uye ukobvu, sezvo izvi zvinhu zvakanyanya kukanganisa kuvimbika kwechigadzirwa chekupedzisira.Nepepa repurasitiki rakanyatsogadzirirwa, unoisa hwaro hwemhedzisiro yethermoforming isina mhosva.

Heat Settings:

Vhura iyo control panel yemuchina wako we thermoforming uye isa tembiricha yekudziya nenguva.Funga nezvehunhu hwepurasitiki zvinhu uye mold zvinodiwa pakuita izvi zvigadziriso.Bvumira muchina we thermoforming nguva yakakwana yekusvika patembiricha yakatarwa, kuve nechokwadi chekuti pepa repurasitiki rinowana kupfava kwaunoda uye kuumbwa kwekunyatso kuumbwa.

Kuumba - Stacking :

Nyatsoisa pepa repurasitiki rinopisa pamusoro pevhu, uchiona kuti rakati sandarara uye rakatsetseka.Tanga maitiro ekuumba, uchiita kuti mold ishandise kumanikidza uye kupisa mukati menguva yakatarwa, neunyanzvi kuumba pepa repurasitiki mune raunoda.Mushure mekugadzira, rega purasitiki isimbise uye itonhodze kuburikidza neforoma, ichienda kune yakarongeka yakarongeka yakarongedza kuti ishande palletizing.

Bvisa Chigadzirwa Chapera:

Nyatsoongorora chigadzirwa chega chega chakapedzwa kuti uone kuti chinosangana nechimiro chinodiwa uye chinonamatira kumhando yepamusoro-soro.Kuongorora kwehungwaru uku kunovimbisa kuti zvisikwa zvisina mhosva chete zvinosiya mutsetse wekugadzira, zvichisimbisa mukurumbira wako wekunaka.

Kuchenesa uye Kugadzirisa:

Kuti uchengetedze mashandiro emidziyo yako ye thermoforming, tora hunyanzvi hwekuchenesa uye kugadzirisa maitiro.Mushure mekushandisa, simbisa iyo thermoforming muchina uye woibvisa kubva kumagetsi sosi.Ita kucheneswa kwakakwana kwe mold uye midziyo yekubvisa chero yasara mapurasitiki kana marara.Gara uchiongorora zvinhu zvakasiyana-siyana zvemidziyo kuti ive nechokwadi chekushanda kwavo kwakakwana, kuchengetedza kusakanganiswa kubereka.