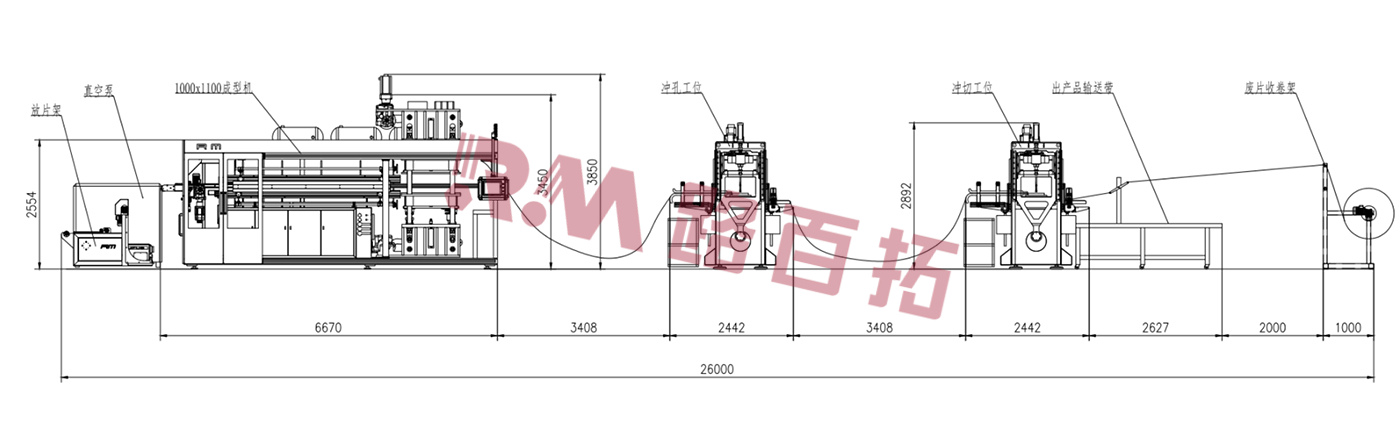

RM-T1011 + GC-7 + GK-7 Thermoforming Machine

Machine Parameters

| ◆Muenzaniso: | RM-T1011 |

| ◆Max. mold size: | 1100mm × 1170mm |

| ◆Max. nzvimbo yekugadzira: | 1000mm × 1100mm |

| ◆Min. Nzvimbo yekugadzira: | 560mm × 600mm |

| ◆Max. chiyero chekumhanya kwekugadzira: | ≤25Times/min |

| ◆Max.Kuumba Urefu: | 150mm |

| ◆ Upamhi hweshizha(mm): | 560mm-1200mm |

| ◆Mould inofamba chinhambwe: | The sitiroko≤220mm |

| ◆Max. clamping force: | kugadzira-50T, kubaya-7T uye kucheka-7T |

| ◆ Simba rekupa: | 300KW(simba rekudziya)+100KW(simba rekushandisa)=400kw |

| ◆Kusanganisira punching muchina 20kw, kucheka muchina 30kw | |

| ◆ Madiro ekupa magetsi: | AC380v50Hz,4P(100mm2+1PE(35mm2) |

| ◆Tree-waya shanu-waya system | |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆ Reducer: | GNORD |

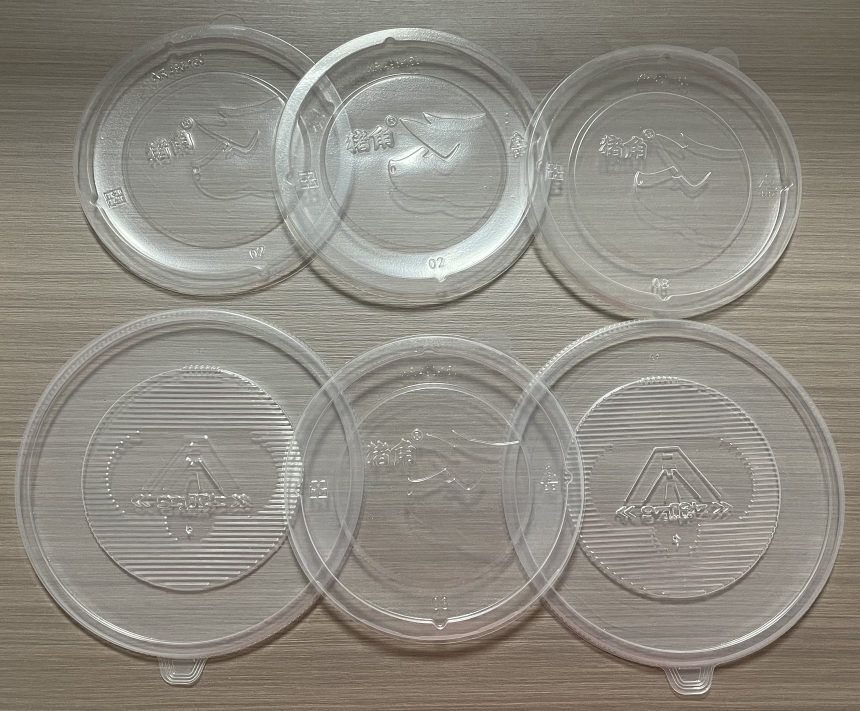

| ◆Kushandisa: | matireyi, midziyo, mabhokisi, zvivharo, nezvimwe. |

| ◆ Zvikamu Zvikuru: | PLC, Injini, Kubereka, Gearbox, Mota, Giya, Pombi |

| ◆Zvishandiso Zvakakodzera: | PP.PS.PET.CPET.OPS.PLA |

| Max. Mold Dimensions | Clamping Force | Chibhakera Capacity | Cutting Capacity | Max. Kuumba Urefu | Max. Air Pressure | Dry Cycle Speed | Max. Kubaya/ Kucheka Dimensions | Max. Kubaya/ Kucheka Kumhanya | Yakakodzera Material |

| 1000*1100mm | 50T | 7T | 7T | 150mm | 6 Bar | 35r/min | 1000*320 | 100 pm | PP, HI PS, PET, PS, PLA |

Product Vhidhiyo

Dhiyagiramu yebasa

Main Features

✦ Kugadzirwa kwakanaka: Iyo yakakura fomati thermoforming muchina inotora nzira yekushanda yeinoenderera yekugadzira mutsara, iyo inogona kuenderera uye nemazvo kupedzisa kuumbwa kwechigadzirwa. Kuburikidza neiyo otomatiki yekudzora sisitimu uye yakakwira-kumhanya mechanicha kushanda, kugona kwekugadzira kunogona kuvandudzwa zvakanyanya kuti isangane nezvinodiwa zvekugadzirwa kwakawanda.

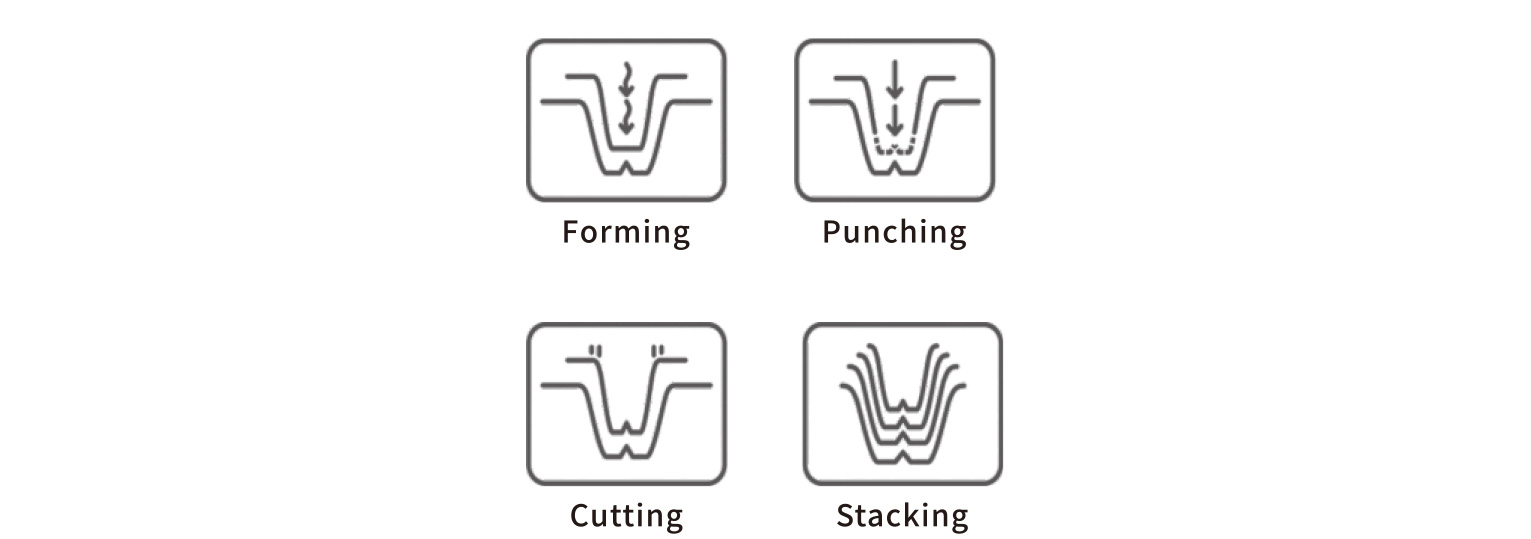

✦ Multifunctional mashandiro: muchina une akawanda mabasa akadai sekugadzira, kubaya, kubaya kwemupendero uye palletizing.

✦ Yakanyatso kuumba uye yemhando yepamusoro zvigadzirwa: Iyo hombe-fomati thermoforming muchina unotora yepamberi yekuumba tekinoroji, inogona kunyatso kudzora kupisa kwekupisa, kudzvanywa uye nguva yekudziya kuti ive nechokwadi chekuti zvinhu zvepurasitiki zvanyungudutswa uye zvakagovaniswa zvakaenzana muforoma, nekudaro kugadzira zvigadzirwa zvine hupamhi hwepamusoro uye kurongeka kwedimensional.

✦ Kushanda otomatiki uye kutonga kwakangwara: Muchina uyu wakashongedzerwa neakanyanya otomatiki sisitimu yekushandisa, iyo inogona kuona mabasa akadai sekudya otomatiki, otomatiki kuumba, otomatiki kubaya, otomatiki edge punching uye otomatiki palletizing. Iko kushanda kuri nyore uye kuri nyore, kuderedza kupindira kwemanyorero, kuvandudza zvakanyanya kugadzirwa kwekugadzira uye kuderedza mutengo wekugadzira.

✦ Chengetedzo uye kuchengetedzwa kwezvakatipoteredza: Iyo hombe fomati thermoforming muchina wakagadzirwa nemhando yepamusoro zvinhu, zvine kusimba kwakanaka uye kugadzikana. Iyo zvakare yakashongedzerwa neyekuchengetedza kuchengetedza system kuti ive nechokwadi chekuchengetedzwa kwevashandisi. Panguva imwecheteyo, muchina uyu une dhizaini inochengetedza simba, iyo inogona kuderedza kushandiswa kwesimba uye kuderedza kukanganisa kwezvakatipoteredza.

Nzvimbo Yekushandisa

Yakakura fomati thermoforming muchina RM-T1011 thermoforming muchina unoshandiswa zvakanyanya muindasitiri yekubika, indasitiri yekurongedza chikafu uye indasitiri yezvinhu zvemumba. Nekuda kwehunyanzvi hwayo hwepamusoro, mabasa mazhinji uye chaiwo maficha, inogona kusangana nezvinodiwa zvekugadzira zvemaindasitiri akasiyana ezvigadzirwa zvepurasitiki uye inopa rutsigiro rwakasimba kumabhizinesi ekuvandudza kugadzirwa kwemhando uye kunaka kwechigadzirwa.

Tutorial

Kugadzirira Kwemidziyo:

Kuti utange muchina wako wekupisa, chengetedza muchina wakakura wakavimbika wekupisa thermoforming RM-T1011 nekusimbisa kubatana kwawo kwakachengeteka nekuubatisa. Cheki yakazara yekudziya, kutonhora, uye kudzvanywa masisitimu kwakakosha kuti uone kushanda kwavo kwakajairika. Chengetedza maitiro ako ekugadzira nekuisa zvine hungwaru ma molds anodiwa, kuve nechokwadi kuti akasimba akamira kushanda zvakanaka.

Raw Material Gadziriro:

Kuwana kukwana mu thermoforming kunotanga nekuchenjerera kugadzirwa kwezvinhu. Nekuchenjera sarudza pepa repurasitiki rakanyatsokodzera kuumbwa, uye simbisa saizi yaro uye ukobvu hunoenderana nezvinodiwa mold. Nekuteerera kune idzi ruzivo, iwe unoseta nhanho yezvigadzirwa zvisingagoneki zvekupedzisira.

Heat Settings:

Vhura iyo yechokwadi kugona kweiyo thermoforming maitiro nehunyanzvi kugadzirisa tembiricha yekudziya uye nguva kuburikidza nepaneru yekudzora. Rongedza zvigadziriso zvako kuti zvienderane nemidziyo yepurasitiki uye mold zvinodiwa, kuwana mhedzisiro yakanaka.

Kuumba - Gomba Punching - Edge Punching - Stacking uye Palletizing:

Isa zvinyoro nyoro pepa repurasitiki rinopisa pamusoro pevhu, kuve nechokwadi kuti yakanyatsoenderana uye isina makwinya kana kukanganisa kunogona kukanganisa maitiro ekuumba.

Tanga maitiro ekuumba, kunyatsoshandisa kumanikidza uye kupisa mukati menguva yakatarwa kuti ugadzire pepa repurasitiki nenzira yaidiwa.

Kana kuumba kwapera, icho chichangobva kuumbwa chigadzirwa chepurasitiki chinosiiwa kuti chiome uye chitonhore mukati me mold, usati waenderera kune gomba kubaya, kupinza punching, uye kurongeka kurongedza kuitira nyore palletizing.

Bvisa Chigadzirwa Chapera:

Ongorora chigadzirwa chega chega chakapedzwa zvine hungwaru kuti uone kuti chinoenderana nechimiro chinodiwa uye chinoteera kune yakatarwa mhando zviyero, uchiita chero shanduko dzinodiwa sezvinodiwa.

Kuchenesa uye Kugadzirisa:

Kana wapedza maitiro ekugadzira, simbisa muchina we thermoforming woubvisa kubva kumagetsi kuti uchengetedze simba nekuchengetedza kuchengeteka.

Nyatsochenesa mold nemidziyo kubvisa chero mapurasitiki kana marara, kuchengetedza hupenyu hurefu uye kudzivirira hurema hunogona kuitika mune ramangwana zvigadzirwa.

Shandisa hurongwa hwekugadzirisa nguva dzose kuti uongorore uye ushandise zvinhu zvakasiyana-siyana zvemidziyo, uchivimbisa kuti muchina we thermoforming unoramba uri muhutano hwakanaka hwekushanda, uchisimudzira kushanda zvakanaka uye hupenyu hurefu hwekuenderera mberi kwekugadzira.