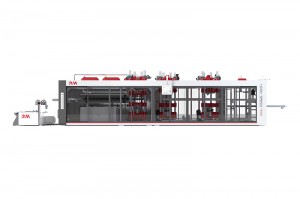

RM-T7050 3 chiteshi otomatiki thermoforming muchina

Machine Parameters

| ◆Muenzaniso: | RM-T7050 |

| ◆Max.Kuumba Nzvimbo: | 720mm × 520mm |

| ◆Max.Kuumba Urefu: | 120mm |

| ◆Max.Sheet Ukobvu(mm): | 1.5 mm |

| ◆ Upamhi hwemapepa: | 350-760mm |

| ◆Maximum sheet roll diameter: | 800mm |

| ◆Kushandisa simba: | 60-70KW/H |

| ◆Mould inofamba chinhambwe: | The sitiroko≤150 mm |

| ◆Kuombera Simba: | 60T |

| ◆Chigadzirwa chekugadzira kutonhora nzira: | Mvura |

| ◆Kunyatsogona: | Max 25cycles/min |

| ◆Electric choto chinopisa simba guru: | 121.6KW |

| ◆ Simba guru remuchina wose: | 150KW |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆ Reducer: | GNORD |

| ◆Kushandisa: | matireyi, midziyo, mabhokisi, zvivharo, nezvimwe. |

| ◆ Zvikamu Zvikuru: | PLC, Injini, Kubereka, Gearbox, Mota, Giya, Pombi |

| ◆Zvishandiso Zvakakodzera: | PP.PS.PET.CPET.OPS.PLA |

| Max.Mold Dimensions | Kumhanya (Kupfura/Maminitsi) | Max.Sheet Ukobvu | Max.Foming Urefu | Huremu hwese | Yakakodzera Material |

| 720x520mm | 20-35 | 2mm | 120mm | 11T | PP, PS, PET, CPET, OPS, PLA |

Product Vhidhiyo

Main Features

✦ Kugadzirwa kwakasiyana-siyana: Iine nzvimbo dzakawanda dzekushanda, iyo 3-chiteshi thermoforming muchina unogona kugadzira zvigadzirwa zvakasiyana kana kushandisa mold dzakasiyana panguva imwe chete, zvichiita kuti maitiro ekugadzira awedzere kushanduka uye akasiyana.

✦ Kukurumidza kuchinja mold: Iyo 3-station thermoforming muchina yakashongedzerwa nekukurumidza mold shanduko system, iyo inogona kukurumidza kushandura mold kuti isangane nezvinodiwa zvekugadzira zvezvigadzirwa zvakasiyana.Izvi zvinoderedza nguva yekuderera uye zvinowedzera kubereka.

✦ Kudzora otomatiki: Iyo midziyo inotora yepamusoro otomatiki kudzora sisitimu, iyo inogona kunyatso kudzora ma paramita akadai sekupisa tembiricha, nguva yekuumba uye kumanikidza.Automated control haingogadziri kugadzikana uye kuenderana kwekuumbwa, asi zvakare inoderedza hunyanzvi hwevashandisi zvinodiwa uye inoderedza zvikanganiso zvevanhu.

✦ Kuchengetedza magetsi uye kuchengetedza simba: Muchina we3-station thermoforming unotora tekinoroji yekuchengetedza simba, iyo inoderedza kushandiswa kwesimba uye mutengo wekugadzira nekugadzirisa kupisa, kutonhora uye kushandiswa kwesimba.Izvi zvakapetwa kaviri mukana wehupfumi uye kuchengetedzwa kwezvakatipoteredza kumabhizinesi.

✦ Zviri nyore kushanda: Iyo 3-chiteshi thermoforming muchina wakashongedzerwa ine intuitive oparesheni interface, uye kushanda kuri nyore kudzidza.Izvi zvinogona kuderedza mari yekudzidziswa kwevashandi uye kuvandudza kushanda kwekugadzira.

Nzvimbo Yekushandisa

RM-T7050 3-chiteshi thermoforming muchina unoshandiswa zvakanyanya muindasitiri yekurongedza chikafu, kunyanya kugadzirwa kwemidziyo yepurasitiki inoraswa, senge mukaka tii mavharo, masikweya mabhokisi, sikweya bhokisi mavharo, mwedzi makeke mabhokisi, Matireyi uye zvimwe zvigadzirwa zvepurasitiki.

Tutorial

Kutanga yako 3 chiteshi thermoforming muchina nekuve nechokwadi chekubatana kwakachengeteka uye simba.

Usati wagadzirwa, ita cheki yakazara yekudziya, kutonhora, kudzvanywa masisitimu, uye mamwe mabasa kuti ave nechokwadi chekuti ari pamusoro-notch mamiriro.

Nekunyatso, isa zviumbwa zvinodiwa zvakachengeteka.Iyi nhanho yakakosha kudzivirira chero kukanganisa panguva yekugadzira uye inova nechokwadi chakafanana, chemhando yepamusoro kubuda.

Kuti uwane mhedzisiro yakasarudzika, gadzira pepa repurasitiki rakakodzera kuumbwa.Sarudzo chaiyo yezvinhu inosimudzira kunaka kwechigadzirwa chekupedzisira uye aesthetics, kumisa zvigadzirwa zvako kubva kumakwikwi.

Simbisa kurongeka pakusarudza ukuru uye ukobvu hwepepa repurasitiki, kuve nechokwadi kuti vanonyatsoenderana nezvinodiwa mold.

Vhura iyo yakazara mukana weiyo thermoforming process nekuisa tembiricha yekudziya uye nguva nehunyanzvi.Funga nezveiyo chaiyo epurasitiki zvinhu uye mold zvinodiwa, uchiita zvinonzwisisika zvigadziriso zvezvakanyanya mhedzisiro.

Neunyanzvi isa pepa repurasitiki rakatsvairwa pamusoro penzvimbo ye mold, uchiona kuti rakarara rakati sandara kuitira mhedzisiro isina mhosva.

Sezvo maitiro ekuumba anotanga, tarisa kuti mold inoshandisa sei kumanikidza uye kupisa mukati menguva yakatarwa, ichishandura pepa repurasitiki kuita chimiro chaunoda.

Mushure mekugadzira, tarisa purasitiki yakaumbwa ichiomesa uye inotonhorera kuburikidza neforoma.Uye ipapo stacking uye palletizing.

Isu tinofanirwa kuenda kuburikidza nekutarisa kwakasimba kune chimwe nechimwe chakapedzwa chigadzirwa.Vaya chete vanosangana nemhando yepamusoro uye yemhando zviyero vanosiya mutsara wedu wekugadzira.

Mushure mekushandisa kwega kwega, inoda kukoshesa kuchengetedza kwemidziyo uye kuchengetedza simba nekudzima muchina we thermoforming uye kuubvisa kubva kumagetsi sosi.

Panguva imwe chete nekunyatso kuchenesa mold nemidziyo, zvichisiya pasina nzvimbo yepurasitiki yasara kana marara anogona kukanganisa kunaka kwekugadzira.

Gara uchiongorora zvikamu zvakasiyana zvemidziyo kuti uvimbise kushanda kwavo kwakakwana.Kuedza kwedu kuenderera mberi mukugadzirisa kunovimbisa kusagadziriswa uye kusingakanganisike kubereka.